|

If you’re looking for an easy-to-use, discreet camera and tech-savvy way to make your day-to-day safe and simple, My Extra Eye is the ideal personal security device for you. It allows you to see anything you want remotely. Simply clip on to your back as you go about town, use it around the house to monitor children or leave it with valuables. My extra eye transmits images and video to your smart phone or tablet. Whatever it is that you need protected, My Extra Eye Has Your Back. www.myextraeye.com TECHNICAL SPECs Resolution 1080p Still Image 8Mp Speed 30fps Viewing Angle 120 deg. Connection WiFi Memory Micro-SD App Android / iOS Size 1.25 * 1.25 * 0.75 inches More than a million athletes experience a concussion in the U.S. each year. Researchers in Southern California are looking at a new way to diagnose concussions in athletes quickly and more easily. Click here to read more.

Employers often forget the benefit of hiring freelance or independent contractors. They get stuck with bad employees and have a hard time realizing ROI. Here is a short list of benefits to hiring a technical contractor, in no particular order...

1. You never pay for employee down time, sick time, PTO, unemployment, or water cooler talk. 2. Eliminate the cost of pricy benefits like (medical, dental, vision, 401K, etc.) 3. Leverage a library of previous work and yield shorter lead times for project completion. 4. Leverage proven designs. 5. Leverage a network of skill sets and capabilities. 6. Save money on capitol equipment like computers, desks, software, test equipment, etc. 7. Circumvent costly and timely SOP and internal bureaucratic standards. 8. Stay within tight cost constraints with fixed cost contracting. 9. Utilize experience from numerous industries and a wide variety of projects. 10. Hire someone that know what it is like to balance the bottom line of their own company and therefore provides you will labor conscious of the ROI principle.

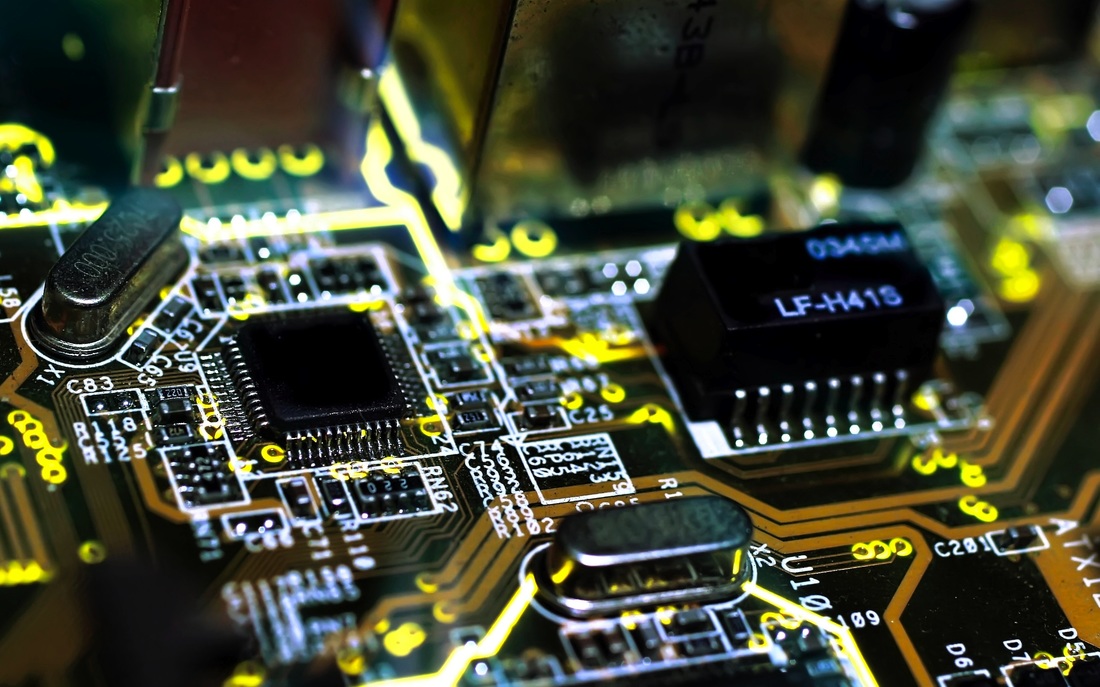

If you ask a lawyer the answer is, "patent your idea, protect it, make it yours." If you ask an engineer, he will say, "start designing, developing, and testing". But what is the right answer? This is really a question of - what is your business's budget and short term goals? If funds are not a problem, I would say do both at the same time, but for the start-up or an independent entrepreneur on a shoe string budget, the answer lies somewhere in-between. THINGS TO CONSIDER BEFORE PATENTING 1. Are you in need of investment? If the answer is yes, than a full patent filing should be on the back burner and not the priority. It is rare that a patent will grab an investor's attention so you are better off paying for the development of a prototype rather than a legal piece of paper. Don't force your benefactors to use their imagination on how great the product or idea is, it is best to let them see and feel it first hand. It is rare that a patent is able to secure investment when no product demos are available. If you are still nervous that you need some protection, and you have a few extra bucks, explore a provisional patent filing. 2. Will my idea get stolen? In my experience, most people are not thieves. In fact, most people are interesting in helping a start-up get traction. Kickstarter is a great example of how people love the start-up. Letting as many people know about your idea could lead to finding a valuable resource for your start-up. Launching a new idea or product is all about great implementation of a product design, manufacturing at the right cost, great marketing, timing, and a little bit of luck. Chances are, you have some but not all of those ingredients, so getting the word out will help refine your sales approach and may provide a valuable resource or future sale for your idea. 3. So I should tell everyone? Yes and no... Assuming your idea is more complex than pounding nails (no offense to nail pounders), Most people do not have all the resources or contacts needed to launch your idea, in that case, you need not to worry about them stealing your idea. In the rare case that you find someone with all the ingredients necessary to implement your idea, chances are, they are doing their own thing. With all that said, there are some rare cases where your lips should be sealed. A WORD OF CAUTION! - 4. Who should I guard my idea from? Do not tell a person / firm who has a market position in your potential industry unless you have a patent and enough money to defend it. Here is an example - A friend of mine pitched a new idea for eye wear to Oakley Sunglasses Company (now Luxottica). In the meeting they told him his idea was terrible, and no deal was made. Within 4 months, he seen his exact product being sold by Oakley. Basically he gave a company that is best positioned to capitalize on a new type of eye wear a great idea and no reason to credit, fund, or utilize him to product it. Oakley had all the engineers, manufacturing, marketing, and positioning to get his idea to marked faster than him. 5. Is it ever too early to share my un-patented idea? Absolutely. Once an idea goes public, you have a year to start some sort of filing before the idea is officially public information and therefore not patentable. If you can't get something filed in a year, do not pitch it. 6. A patent is only as good as your ability to defend it. Court fees, depositions, expert witnesses, and lawyers are not cheep and always take way too much time. Remember that to your benefit. 7. Patents are valuable, but not 100% fool proof protection. I like to say that a patent is like a chain link fence. It keeps out the lazy, uninformed, and cautious, but the young and fearless may just climb over it with innovation and creativity. 8. Provisional patents can be used to lock in protection without the expense of a full filling. Although a provisional will expired in a year unless converted to a full patent, they are useful to lock in a date when the invention was conceived and protect your idea. Provisionals are fairly straight forward to file, and they provide you with a Patent Pending status. There are some secrets to filing a effective provisional. We can help you navigate this process or even extend the usefulness of a provisional patent. For more details - Crowdfunding, in general, is a tough game. According to Kickstarter, only a third of all projects launched, reach their funding goal. When you add in the intricacy of promoting a niche product or a new invention, the level of difficulty skyrockets. Here is one simple metric you can use to determine if you will be successful with your crowd funding campaign. Its just simple math based on crowd funding marketing statistics. THE FUNDING CRITERIA - Assuming you have an idea or product that is priced fairly and is well suited for crowed funding - Will your network support size support your campaign? Based on www.kicktraq.com data, the best campaigns may achieve a 10% conversion rate if they have warm leads and generous friends, but a more realistic conversion rate is 3% or less - So with a 3% or less rate, a $100K funding goal, and a average contribution of $100, you will need to drive way more than 33,000 people to your kickstarter to achieve your goal. Don't rely on your campaign going viral on it's own, make sure you can get at least 33,000 folks to come check it out. In summary, here is the formula - Total funding goal / average contribution / conversion rate (0.03 or lower) Bad PCB designs are an epidemic now days. Most young engineers either come out of school with no knowledge on good layout practices, or older engineers have bad habits that derive from old manufacturing processes. The consequence of a bad layout are very significant, your design will not be legally sold if it does not pass the appropriate test associated with your industry ( FCC part 15, UL, IEC60601, DO-160, Mil-STD, etc.). Your layout can make the difference in these types of tests. Why does this mater? A bad PCB design can cost you big. It can rack up additional lab fees, consulting costs, and redesign time and materials. In one case, I seen a bad PCB design cost an Aerospace program over $450K. They hired inexperienced designers, and they spent a ton of time in the lab troubleshooting a horrible design. Allow me to brag, Coaction consulting has designed over 150 pcb(s) and each one has passed the testing necessary to launch the product. This is no accident, it has been the result of years of training and experience. So without further ado, here is a small list of do's and don'ts - DO USE ALTIUM DESIGNER, DON'T USE ALLEGRO, EAGLE, OR MENTOR Altium has fantastic tools like 3D board layout (Mechanical CAD generation .iges .step file) that save you tons of money since your mechanical engineer will not have to draw a PCB to fit in his product design. It's like electro-mechanical integration for free. It also has great BOM tools for tracking world wide part inventory and lifetime data. Other CAD packages offer these tools as costly add ons, and it's a general rule of thumb that Altium is offering the bast bang for the buck if you are a system integrator, plus the layout is intuitive. DON'T EVER SPLIT GROUND PLANES AND RUN SIGNAL LINES ACROSS IT If you split your planes, analog on one side and digital on another, then you run a signal across it, you are killing your design. The electrical return path of a signal prefers to always runs directly under a trace, if you split your plane you have created an antenna. Get ready for more noise not less. If you want to keep noisy traces or components from sensitive components, just locate them on opposite ends of the boards. Don't be a fool, although split planes may be intuitive, when you analyse the physics, it is just the opposite. I have seen this mistake cost companies hundreds of thousands of dollars and old engineers big headaches and humbling experiences. Use Dr. W Micheal Kings (the guru) 3W RULE If you want to know how far to place a noisy trace from a sensitive one. Generally it is 3 times the width of the trace. So, if the trace is 10 mils, locate the next trace 30 mils away. Of course, alway place differential pairs as close together as possible. Also, any digital signal with a frequency less that that of RS232 will not be noisy if the ground plane is NOT SPLIT. DON'T PLACE FILTERS OVER GROUND PLANES If you locate a filter (inductor or ferrite bead) under a ground plane, the parasitic capacitance of the PCB board will create an AC short and there will be a diminishing filtering effect. The best practice is to have a ground plane keep out zone under the filter. Also, keep the filters at the board edges right by connectors or shields. Remember, NO SPLIT GROUND PLANES. DO USE LOTS OF VIA TO EQUALIZE THE POTENTIAL LEVELS ON GROUND PLANES Via(s) between plains can keep the noise levels down on your design. Don't worry, it will not cost that much in the manufacturing process and it will be well worth it once you start your certification testing. DO HIRE A COACTION ENGINEER FOR YOUR NEXT LAYOUT Well, this one goes without saying. ;) For more info, follow the link - http://www.coactionconsulting.com/electronic-engineering.html Special Thanks to: http://www.systemsemc.com/ Click, watch, enjoy! Consumer Electronics -

Medical Devices -

Aerospace & Industrial -

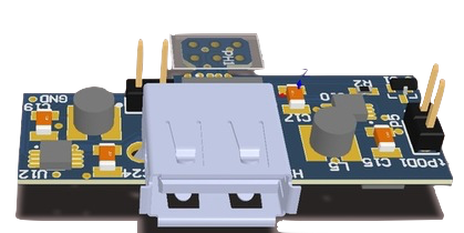

Most new tech products revolve around mobile or internet connectivity. If you want to compete, these features are a must have. Coaction has the capability to integrate either of these technologies into your next product. We have numerous engineers capable of programming your mobile app in iOS or android. Also, our engineers have numerous years of experience with wifi, bluetooth, usb, etc.

Drop us a line we would love to help you get your product connected. We don't like to scare anyone, but launching a product is a literal mine field of work, problems, and dilemmas. It takes the right amount of bravery and experience to achieve a successful launch. Lets start with just a few of the questions an entrepreneur or project manager might face -

Is my concept marketable? What technology should I use? Is there a patent that prevents me from implementing my product idea? Should I get a patent? How do I get it design on a budget? How do I raise money? How and where do I manufacture? Quality? How do I market? How do I generate income or sales? Distribution? Does this sound complicated? The good news is, your not alone. Coaction consulting has proven experience advising clients on the right path for their product, budget, and capabilities. Drop us a line, we would love to help. Need an NDA? No problem, our lips are sealed. Don't crash and burn, let us help. Utilizing the right process and partnering with the lowest cost manufacturer could determine if your product is price right for the market. With 15 years of experience, Coaction has created some amazing techniques/secrets to ensuring that your manufacturing will be the most cost effective for your market niche.

Its not as easy as you think. When manufacturing you can see prices that vary by 1000% and quality differences that do not justify the price range. Let Coaction help you navigate the complicated manufacturing world. Some have rightly compared the manufacturing world to the wild, wild, west. Our expertise - PCB, PCBA, Injection molding, Machining, Extrusions, Assembly, etc. If you need money for your start-up, what is the best way to get it. Investment will cost you equity, control, and it is not necessarily easy to get. Let CoAction help you navigate the free money playing field so your idea gets funded with the least impact to your bottom line. Does this sound to good to be true? Send us an email we would love to prove it to you.

[email protected] Making your news SPLASH!CoAction Consulting can help you with your strategy to get noticed. As a testimonial, just look at the media success for FOGO. This simple strategy yielded over 100 online articles, awards, acknowledgments, prize money, and numerous request for print and TV.

Stay tuned most our blogs are a work in progress. |

AuthorCoaction Staff Writers Archives

August 2017

Categories

All

|

How We can Help

|

Project Management

Electronics Product Design Wireless Product Design Printed Circuit Board PCB Layout Printed Circuit Board PCB Fabrication Embedded & Firmware Development Embedded RTOS (Stratify) Industrial Design Mechanical Design FEA Surfacing Internet of Things IoT Website Design Mobile App Development IOS & Android |

Aerospace Engineering

Medical Product Development Consumer electronics Industrial Application Design HIPAA Compliance Network Compliance Testing - IEC60601 - DO160 -Mil Spec 810F Manufacturing ISO6001 AS60001 Mechanical Engineering Electrical Engineering Software Engineering Regulatory Affairs Consulting |

RSS Feed

RSS Feed